- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Choose the right Truck Tyre

- Certifications

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

- Features:

• Designed for forklift vehicles operating in port, airport, factory and warehouse sites, etc.

• Special compound producing good cutting, wear resistances, long lift service

• Wide and thick tread design providing good ground contact, traction and self-cleaning

Applications:

Electric Forklift Tires

Counterbalanced Forklift tires

Tires for Heli, Hangcha , EP, Toyota, Crown, linde, NOBLIFT, Hyster, STILL, Tailift,Cat, jungheinrich, BT, BYD

Other Details:

•Official warranty policy could supply.

•OEM is acceptable

•Delivery Time: 10-30 days after the receipt of deposit

•Payment: L/C, T/T, Paypal

•MOQ:1*20GP,Mixed sizes are allowed

ABOUT SOLID Tire:As a professional manufacturer of solid tyre, protector and tyre patch, and can provide pneumatic rim type solid tyre, press-fit solid tyre, eco-friendly solid-core tyre, tractor, trailer solid tyre and a variety of nonstandard solid tyres compliant with TRA, ETRTO, JATMA standards by introducing the most advanced solid tyre design and production technology in the world. Our products are featured by extremely high wear resistance, very low rolling resistance, great lifespan, maintenance freedom and piercing resistance.

We always insist on the tenet of "Quality First, Customer Supreme, Quality Service, Contract Honored", and develop reciprocal cooperation with customers at home and abroad with high-quality product, good reputation and best service for common development and a brilliant future!

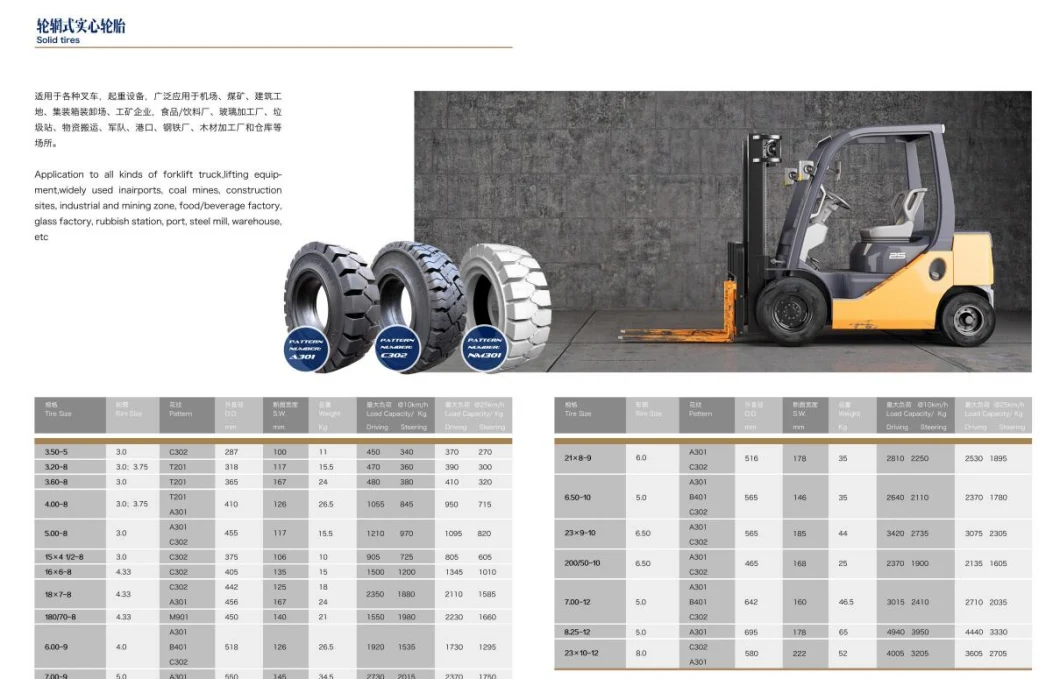

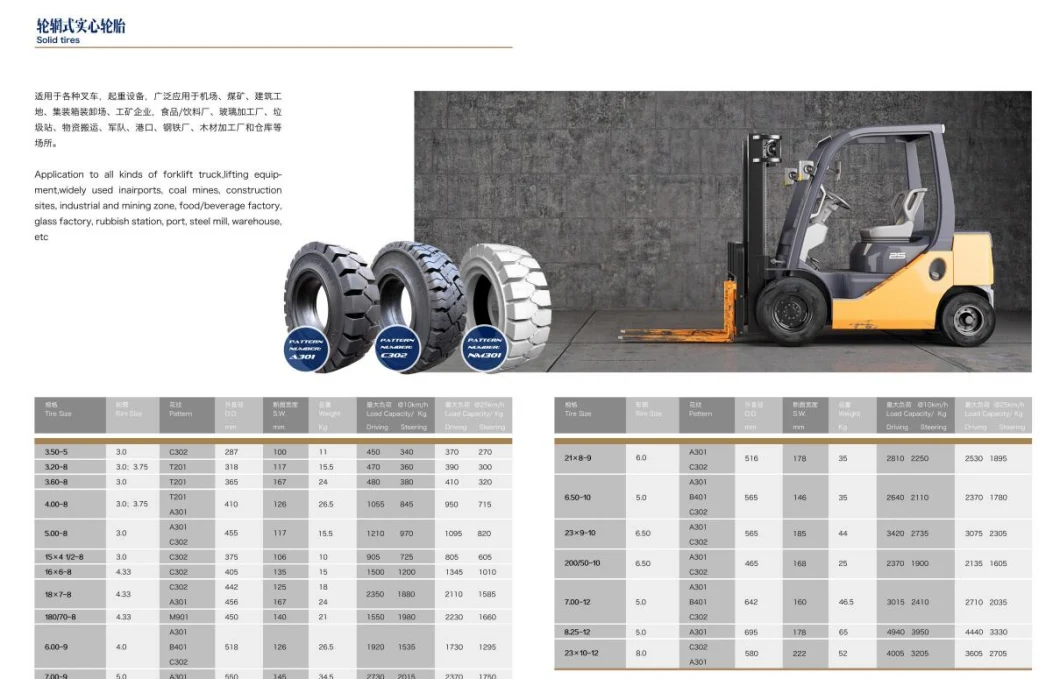

| SIZE (inch) | Rim Size(inch) | Pattern | Outside Diameter | Section Width | Weight | FOB USD QINGDAO | CBM |

| ±5mm | ±5mm | ±1.5%kg | |||||

| 3.50-5 | 3.0 | ZC-C302 | 287 | 88 | 5 | 13 | 0.007 |

| 3.20-8 | 3.0;3.75 | ZC-T201 | 318 | 94 | 6 | 13 | 0.01 |

| 4.00-8 | 3.0;3.75 | ZC-T201 ZC-A301 | 410 | 100 | 11 | 21 | 0.017 |

| 5.00-8 | 3.0;3.5 | ZC-A301 ZC-C302 | 455 | 117 | 15.5 | 31 | 0.024 |

| 15×4 1/2-8 | 3.0;3.33 | ZC-C302 ZC-S601 | 375 | 106 | 10 | 20 | 0.015 |

| 16×6-8 | 4.33 | ZC-C302 | 405 | 135 | 15 | 30 | 0.022 |

| 18×7-8 | 4.33 | ZC-C302 ZC-A301 | 442 456 | 125 167 | 18 24 | 36 48 | 0.025 0.035 |

| 180/70-8 | 4.33 | ZC-M901 | 450 | 140 | 21 | 42 | 0.03 |

| 6.00-9 | 4.0 | ZC-A301 ZC-B401 ZC-C302 | 518 | 126 | 26.5 | 53 | 0.034 |

| 7.00-9 | 5.0 | ZC-A301 | 550 | 145 | 34.5 | 69 | 0.044 |

| 21×8-9 | 6.0 | ZC-A301 ZC-C302 | 516 | 178 | 35 | 70 | 0.047 |

| 6.50-10 | 5.0 | ZC-A301 ZC-B401 ZC-C302 | 565 | 146 | 35 | 70 | 0.047 |

| 23×9-10 | 6.50 | ZC-A301 ZC-C302 | 565 | 185 | 44 | 88 | 0.06 |

| 200/50-10 | 6.50 | ZC-A301 ZC-C302 | 465 | 168 | 25 | 50 | 0.036 |

| 7.00-12 | 5.0 | ZC-A301 ZC-B401 ZC-C302 | 642 | 160 | 46.5 | 92 | 0.066 |

| 8.25-12 | 5.0 | ZC-A301 | 695 | 178 | 65 | 130 | 0.086 |

| 23×10-12 | 8.0 | ZC-C302 ZC-A301 | 580 570 | 222 208 | 52 46 | 105 92 | 0.075 |

| 27×10-12 | 8.0 | ZC-A301 ZC-C302 | 665 655 | 230 221 | 73 69.5 | 146 139 | 0.1 |

| 5.50-15 | 4.5 | ZC-A301 | 680 | 146 | 45 | 90 | 0.068 |

| 6.00-15 | 4.5 | ZC-A301 | 705 | 155 | 48 | 96 | 0.077 |

| 6.50-16 | 5.5 | ZC-A301 | 675 | 144 | 44 | 96 | 0.066 |

| 7.00-15 | 5.50;6.00 | ZC-A301 | 740 | 177 | 67.5 | 135 | 0.097 |

| 7.00-16 | 5.50;6.00 | ZC-A301 | 805 | 170 | 80.5 | 165 | 0.11 |

| 7.50-15 | 5.50,6.00 | ZC-A301 | 740 | 176 | 67.5 | 135 | 0.097 |

| 7.50-16 | 5.50;6.00 | ZC-A301 | 805 | 170 | 82 | 165 | 0.11 |

| 8.25-15 | 6.5 | ZC-A301 | 800 | 198 | 88 | 180 | 0.127 |

| 8.25-16 | 6.5 | ZC-A301 | 815 | 190 | 88 | 180 | 0.126 |

| 28×9-15(8.15-15) | 7.0 | ZC-A301 ZC-B401 ZC-C302 | 700 | 210 | 64 | 126 | 0.1 |

| 250-15 | 7.0 | ZC-A301 | 700 | 202 | 72 | 145 | 0.1 |

| 300-15 | 8.0 | ZC-A301 | 791 | 233 | 106 | 228 | 0.146 |

| 355/65-15 | 9.75 | ZC-A301 | 791 | 283 | 120 | 258 | 0.18 |

| 9.00-16 | 6.5 | ZC-E3 | 832 | 230 | 106.5 | 220 | 0.16 |

| 16/70-16 | 10.0 | ZC-SKS | 890 | 275 | 148.5 | 310 | 0.218 |

| 20.5/70-16 | 10.0 | ZC-SKS | 890 | 275 | 148.5 | 310 | 0.218 |

| 30X10-16 | 6.0 | ZC-SKS | 740 | 235 | 71 | 145 | 0.13 |

| 30X10-16 | 6.0 | Smooth | 780 | 233 | 90 | 182 | 0.15 |

| 33X12-20 | 8.0 | ZC-SKS | 830 | 280 | 96 | 193 | 0.2 |

| 33X12-20 | 8.0 | Smooth | 823 | 288 | 112 | 224 | 0.2 |

| 10-16.5 | 8.3(212) | ZC-SKS | 775 | 248 | 96 | 192 | 0.149 |

| 12-16.5 | 10.00(252) | ZC-SKS | 825 | 278 | 124.5 | 249 | 0.189 |

| 8.25-20 | 6.50,7.00 | ZC-A301 | 935 | 200 | 112 | 238 | 0.175 |

| 9.00-20 | 6.50,7.00 | ZC-A301 | 945 | 210 | 134 | 280 | 0.188 |

| 10.00-20 | 7.5,8.0 | ZC-A301 | 1040 | 253 | 189 | 390 | 0.274 |

| 11.00-20 | 7.5,8.0 | ZC-A301 | 1050 | 265 | 200 | 415 | 0.297 |

| 12.00-20 | 8.0,8.5 | ZC-A301 | 1105 | 260 | 237 | 490 | 0.212 |

| 12.00-20 | 8.0,8.5 | smooth | 1110 | 240 | 240 | 498 | 0.3 |

| 12.00-24 | 8.5 | ZC-A301 | 1140 | 300 | 246 | 510 | 0.4 |

| 14.00-24 | 10.0 | ZC-A301 | 1295 | 308 | 345 | 715 | 0.5 |

| 14.00-24 | 10.0 | ZC-C302 | 1300 | 340 | 395 | 820 | 0.6 |

| 14-17.5 | 8.0 | ZC-SKS | 1010 | 310 | 170 | 355 | 0.32 |

| 16/70-20 | 13.00.(324) | ZC-SKS | 1015 | 375 | 259 | 540 | 0.386 |

| 20.5/70-20 | 8.0 | ZC-SKS | 875 | 278 | 118 | 245 | 0.316 |

| 36*12.5-20 | 9.0 | ZC-E3/L3 | 895 | 291 | 140 | 290 | 0.24 |

| 41x14-20 | 11.5 | ZC-A301 | 1040 | 352 | 256 | 530 | 0.38 |

| 385/65-24 | 10.0 | ZC-SKS | 1040 | 338 | 194 | 402 | 0.36 |

| 445/65-24 | 10.0 | ZC-D501 | 1128 | 432 | 353 | 780 | 0.55 |

| 14.00-25 | 10.0 | ZC-C302 | 1300 | 340 | 395 | 820 | 0.6 |

| 16.00-25 | 11.25 | ZC-L5 | 1365 | 370 | 484 | 1080 | 0.7 |

| 17.5-25 | 14.0 | ZC-E3/L3 | 1350 | 415 | 533 | 1200 | 0.8 |

| 17.5-25 | 14.0 | ZC-L5 | 1365 | 370 | 500 | 1120 | 0.7 |

| 18.00-25 | 13.0 | ZC-L5 | 1580 | 420 | 765 | 1750 | 1.05 |

| 20.5-25 | 17.0 | ZC-L5 | 1400 | 470 | 648 | 1480 | 0.92 |

| 23.5-25 | 19.5 | ZC-E3/L3 | 1580 | 550 | 1050 | 2500 | 1.4 |

| 23.5-25 | 19.5 | ZC-L5 | 1580 | 502 | 960 | 2250 | 1.3 |

| 26.5-25 | 22.0 | ZC-L5 | 1680 | 620 | 1300 | 3250 | 1.75 |

| 29.5-25 | 26.5 | ZC-L5 | 1830 | 690 | 1840 | 4650 | 2.344 |

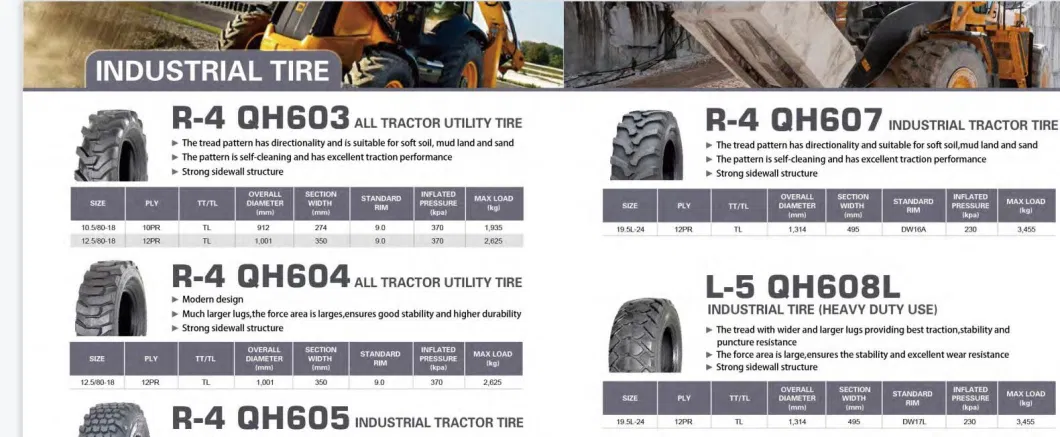

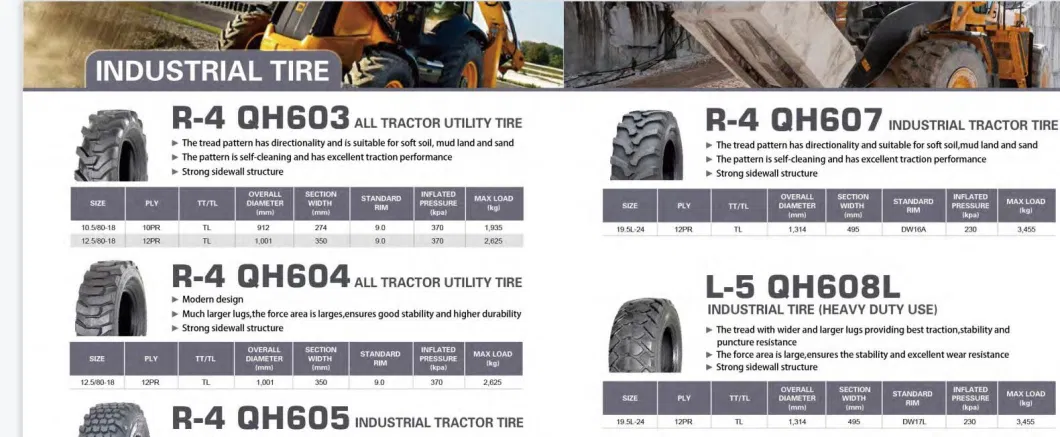

Construction and Structure of tires

When it comes to selecting the right truck and construction vehicle tire patterns based on road conditions and work environments, several factors should be considered. Here are some key considerations and corresponding tire patterns:

Highway/Tarmac Roads:Ribbed or highway tread patterns: These tires feature continuous ribs along the circumference, providing excellent stability, traction, and reduced rolling resistance for smooth highways and tarmac roads.

Off-Road/Construction Sites:

All-Terrain tread patterns: These tires have a balanced design, featuring moderate-sized lugs and voids. They offer good traction on both paved surfaces and off-road terrains, making them suitable for construction sites and moderate off-road driving.

Muddy/Wet Conditions:

Mud tread patterns: These tires have deep, widely spaced lugs and aggressive self-cleaning properties to enhance traction in muddy or wet conditions. They prevent mud buildup and maintain grip, making them ideal for muddy construction sites and off-road applications.

Rocky/Tough Terrains:

Rock or lug tread patterns: These tires feature large, robust lugs with enhanced sidewall protection. They provide excellent traction and durability in rough terrains, such as rocky construction sites or off-road environments with challenging obstacles.

Winter/Snowy Conditions:

Snow or winter tread patterns: These tires have specialized tread designs with a higher number of sipes, biting edges, and unique rubber compounds for enhanced traction on snow and ice. They are crucial for trucks and construction vehicles operating in regions with severe winter weather.

Heavy Load Carrying:

All-Position or Wide-Base tread patterns: These tires are designed to carry heavy loads evenly. They have a wider contact patch, reinforced sidewalls, and robust construction, making them suitable for trucks and construction vehicles that frequently transport heavy loads.

It's important to consult with tire manufacturers, dealers, or industry experts to identify specific tire patterns that best suit your requirements. Additionally, considering the tire's load-carrying capacity, speed rating, and overall quality is crucial in ensuring optimal performance and safety in various road and work conditions.

It's important to note that not all truck tires require inner tubes, especially modern radial tires with tubeless technology. However, in specific usage scenarios and road conditions where additional support, puncture resistance, or temperature stability is required, using inner tubes can be a practical solution. Consulting with tire experts or manufacturers can provide specific guidance on whether inner tubes are necessary for a particular truck tire and its intended application.

GUIDELINE ON HOW TO USE TYRES

1.Tyre and Rim

(1) Check carefully before tyre mounting to see if the rim sizes are identical to those marked on sidewalls.

(2) The tyre should be fitted as much as possible to standard rims or allowable rim range.

(3) The tyre should not be fited to deformed rims or non-conformity rims. warning:

Deformed rims or non-conformity rims will result in premature tyre toe failure or blow out to hurt People.

2.Inflated Pressure

(1) Rules should be followed to inflate the tyre.

(2) It is not appropriate to inflate the tyre over pressure and then release the air to standard pressure.

(3) Check the tyre pressure regularly and replenish when the air pressure is not found sufficient. Warming:

Tyre under-pressure will cause decreased loading capacity, easy cord breaking and dangerous blow out, Tyre overpressure will cause cord strength loss and dangerous blow out.

3.Load

(1)Select the tyre of corresponding ply rating and load based on the vehicle's standard loading capacity.

(2) The tyre of low ply rating can not bear high load. The tyre load Mn not be increased by the increase of inflated pressure.

(3) The load should be distributed evenly on the vehicle. Warning:

Overload will cause a serious injury to the tyre or the People. The vehicle with the load unevenly distributed will cause some of tyres serious overload,which is one of the factors causing accidents.

4.Speed

The tyre should match the vehicle in operating speed and operate in the range of specified speed for vehicle.

Warning

Overspeed will cause quicker tread wear,rapid heat build up,tyre strength deterioration,separations and even tyre blow out.

Our company offers international logistics services that are cost-effective, efficient, and secure. Here is a brief overview of the services we provide for a high-quality one-stop international procurement experience, from factories to destination ports:

Competitive Pricing: We strive to offer competitive pricing without compromising on service quality, ensuring that our clients receive the best value for their international logistics needs.

Efficient Operations: Our experienced team manages the entire logistics process, including documentation, customs clearance, cargo consolidation, and transportation arrangements. We focus on efficiency to streamline operations and deliver goods promptly.

Seamless Experience: We provide a comprehensive one-stop solution, handling all aspects of the international procurement process. From coordinating shipments to managing logistics, our goal is to make the experience seamless and hassle-free for our clients.

Real-time Tracking: Utilizing advanced tracking systems, we offer real-time monitoring of shipments, keeping our clients informed about the status of their goods. This transparency enables them to have visibility and peace of mind throughout the transportation journey.

Safety and Security: We prioritize the safety and security of our clients' cargo. Our network of trusted partners and service providers ensures that goods are handled and stored in secure facilities, minimizing the risk of damage or loss.

In summary, our international logistics services provide a cost-effective, efficient, and secure solution for clients seeking a high-quality one-stop international procurement experience. From factory to destination port, we prioritize efficiency, transparency, and the safety of goods to deliver a seamless logistics experience for our clients.

Q1. What is your terms of payment? A: T/T, L/C, PayPal, West Union. 30% T/T in advance, 70% balance against by copy of B/L

Q2. What is your terms of delivery? A: FOB, CIF, CFR

Q3. How about your delivery time? A: Usually, it will take 30 to 45 days after receive your deposit. In fact the delivery time according to your order quantity.

Q4. Can you produce according to the samples and confirm the quality? A: Yes, we will produce the same to the sample, our engineer and quality control team will manage the production and check each step one by one to make sure that the final products are qualified before shipment.

Q5. What is your accepted payment Currency? A: USD or RMB(Less).